Locations

Introducing LOTTE BIOLOGICS' production facilities,

renowned for their top-tier quality and manufacturing capabilities.

CDO

LOTTE BIOLOGICS offers development service capabilities across the product life cycle, including product launches, scale-down process verification, and technology transfers.

CMO

LOTTE BIOLOGICS offers cGMP manufacturing services for the clinical and commercial supply of biological Drug Substance.

Analytical Testing Services

LOTTE BIOLOGICS offers quality control testing services including analytical tech transfer, in-process testing, finished product testing, and stability testing.

Quality

With robust quality systems and proven regulatory track records at our GMP facility, we supply the highest quality products to our customers.

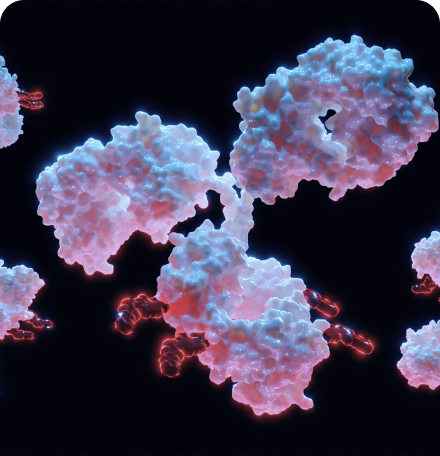

ADC Service

Our services include the conjugation of ADCs which combine the specificity of monoclonal antibodies with the potency of small-molecule drugs through the use of stable linkers.

NEWSROOM

Delivering the latest news from LOTTE BIOLOGICS.